The hot runner system generally consists of several parts, including a hot nozzle, a splitter plate, a temperature control box, and accessories. There are generally two types of thermal nozzles: open type and needle valve type. Due to the fact that the form of the hot nozzle directly determines the selection of the hot runner system and the manufacturing of the mold, the hot runner system is often divided into an open hot runner system and a needle valve hot runner system accordingly. The splitter plate is used when the first mock examination has multiple cavities or multi-point feeding, single point feeding, but the material level is offset. The material is usually P20 or H13. The splitter plate is generally divided into two categories: standard and non-standard, and its structural form is mainly determined by the distribution of the cavity on the mold, nozzle arrangement, and gate position. The temperature control box includes the host, cables, connectors, and wiring male and female sockets. Hot runner accessories typically include heaters and thermocouples, runner sealing rings, connectors, and junction boxes. Generally speaking, hot runner systems are divided into single head hot runner systems, multi head hot runner systems, and valve gate hot runner systems. The single head hot runner system mainly consists of a single nozzle, nozzle head, nozzle connecting plate, temperature control system, etc.

The plastic mold structure of the single head hot runner system is relatively simple. Inject molten plastic from the injection molding machine into the nozzle connecting plate, and after reaching the nozzle head through the nozzle, inject it into the mold cavity. It is necessary to control the dimensions d, D, L, and adjust the thickness of the nozzle connecting plate to make the fixed mold fixed plate compress the end face of the nozzle connecting plate, control the axial displacement of the nozzle, or directly use the injection molding machine nozzle to support the end face of the nozzle connecting plate, which can also achieve the same goal. Install a lead slot at a suitable position on the fixed plate of the mold, allowing the power cord to be led out of the mold and connected to the wiring base installed on the mold.

The plastic mold structure of the multi head hot runner system is relatively complex. Molten plastic is injected into the nozzle connecting plate by the injection molding machine, flows through the hot runner plate to the nozzle, reaches the nozzle head, and then injects into the mold cavity. The nozzle of the hot runner system has radial dimension D1 matching requirements and axial dimension limit requirements with the fixed template. The nozzle head and the fixed mold insert have radial size d matching requirements to ensure that the molten plastic does not overflow into the non mold cavity, and the hardness of the fixed mold insert is required to be hardened to about 50HRC. The distance L between the parting surface and the axial positioning surface of the hot nozzle must be strictly controlled. This size should be based on the actual distance L 'of the nozzle at room temperature, plus the actual extension of the nozzle at normal working temperature of the mold Δ L OK. In order to ensure reliable adhesion between the nozzle and the hot runner plate and prevent deformation of the hot runner plate, an adjustment pad is installed above the top of the nozzle, which, together with the axial positioning surface of the nozzle itself, limits the axial movement of the nozzle and effectively controls the possible deformation of the hot runner plate. At room temperature, control the 0.025mm gap between the adjustment pad and the hot runner plate and the fixed mold plate to ensure that the pad is tightly pressed during the working temperature state after the mold is heated. The positioning seat and positioning pin of the hot runner system together control the position of the hot runner plate in the mold. The positioning seat and the fixed template have radial dimension D2 matching requirements, and the depth h must be accurately controlled. The axial direction of the positioning seat plays a role in supporting the hot runner plate and directly bears the injection pressure of the injection machine. There are matching requirements between the positioning pin and the fixed plate of the hot runner plate. There must be sufficient clearance between the hot runner plate and the template to wrap the insulation material. The hot runner plate and fixing plate must have sufficient wiring slots to allow the power cord to be led out of the mold and connected to the wiring base installed on the mold. There is a radial dimension D1 matching requirement between the nozzle connecting plate and the fixed mold plate, in order to ensure a good fit between the injection head of the injection molding machine and the nozzle connecting plate on the mold. Near the hot runner plate, connect the fixed template, hot runner plate fixing plate, and fixed mold fixing plate with screws to enhance the rigidity of the hot runner plate.

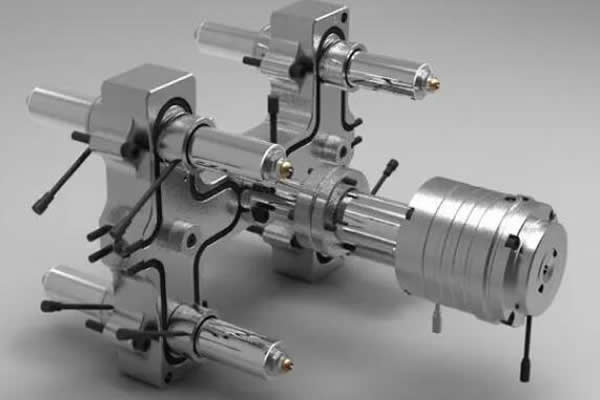

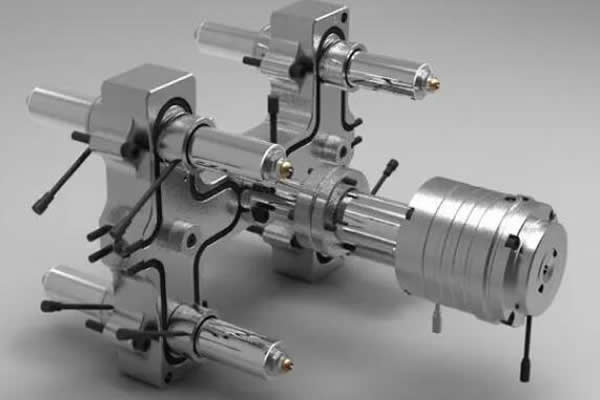

The plastic mold structure of the valve gate hot runner system is the most complex. It has the same structure as the ordinary multi head hot runner system plastic mold, and also has an additional valve needle transmission device to control the opening and closing movements of the valve needle. This transmission device is equivalent to a hydraulic cylinder, which is connected to the mold using the hydraulic device of the injection machine to form a hydraulic circuit, achieving the opening and closing movement of the valve needle, and controlling the injection of molten plastic into the mold cavity. Firstly, determine the position of the feeding port based on the structure and usage requirements of the plastic parts. As long as the structure of the plastic part allows, the nozzle and nozzle head inside the fixed mold insert do not interfere with the forming structure, and the feeding port of the hot runner system can be placed at any position of the plastic part. The position of the feed inlet for conventional injection molding of plastic parts is usually selected based on experience. For large and complex shaped plastic parts, computer-aided analysis (CAE) can be used to simulate the flow of molten plastic in the mold cavity, analyze the cooling effect of various parts of the mold, and determine the ideal feeding port position for injection molding.

Secondly, determine the nozzle head form of the hot runner system. The material and product usage characteristics of plastic parts are key factors in selecting the nozzle head form, and the production batch of plastic parts and the manufacturing cost of molds are also important factors in selecting the nozzle head form.

Thirdly, determine the number of cavities per mold based on the production batch of plastic parts and the tonnage of injection equipment.

Fourthly, the number of nozzles is determined by the determined position of the feeding port and the number of cavities per mold. If a certain product is formed and one feeding port is selected for one piece of the first mock examination, only one nozzle is required, that is, single head hot runner system is selected; If a certain product is formed and multiple cavities in the first mock examination or more than two feeding ports in one cavity in the first mock examination are selected, multiple nozzles are required, that is, multiple head hot runner system is selected, except for the mold structure with cross runners.

Fifth, determine the radial size of the nozzle based on the weight of the plastic part and the number of nozzles. The same form of nozzle has multiple size series, which meet the forming requirements of plastic parts within different weight ranges.

Sixth, determine the size of the mold structure based on the plastic part structure, and then select the standard length series size of the nozzle based on the thickness size of the fixed mold insert and the fixed template. Finally, adjust the thickness size of the fixed template and other dimensions related to the hot runner system.

Seventh, determine the shape of the hot runner fixing plate based on the shape of the hot runner plate, arrange power cord lead slots on the plate, and design sufficient cooling water loops near the hot runner plate, nozzle, and nozzle head.

Eighth, complete the design drawing of the plastic mold for the hot runner system.

Ninth, a mature hot runner system must consider the degree of coordination between the hot runner system and the plastic mold, that is, the design of the hot half mold. Hot semi mold refers to a precision hot runner system processed by specialized hot runner manufacturers for customers, which has the characteristics of simple and convenient maintenance, high matching accuracy, and fast processing Reduce injection pressure and locking force. An important step in hot runner design is the concept of hot runner design. A detailed design concept, including manifold and pressure plate, will become an important part of the mold review.

The manifold is used to ensure that the molten channel can be arranged in the most effective way. In an ideal situation, the molten channel is designed in a symmetrical manner, and the flow length and number of turns in all downstream channels are consistent. In the case of using multi cavity molds or asymmetric molds, the melt channel may include artificial lengths and turning points to properly balance the system. This concept is helpful for both designers and hot runner designers, ensuring optimal manifold design.

On a part that requires three injection ports, in order to control the seam line on the part, it is necessary to solve the problem of plastic flow balance. Through a detailed manifold design, the balance of flow and the layout of the manifold can be evalsuated to ensure that the downstream flow channel can meet the needs of the customer's mold base. The final result is to combine a single direct injection port and two injection ports from hot to cold on a single cavity mold (Figure 3).

In addition, pressing plate technology should be adopted to ensure that the closure height and key features required by the customer can be designed. Due to the inclusion of a hot runner nozzle in the nozzle, the mold designer also needs to confirm whether the proximity of the injection port and cooling can meet the requirements of the hot runner manufacturer.

The main factors for evalsuating the hot runner include: flow balance and heat distribution in the manifold; Channel size; Strength of manifold materials in high-pressure applications; The size of the injection port; Proximity of cooling and injection ports; Capable of withstanding abrasive and corrosive resin components.

Hot runner is a complex and advantageous mold component. In mold production projects, CAE computer-aided engineering analysis, resin testing, and design concepts can all be completed by hot runner suppliers. In the early stages of a project, if the hot runner supplier is involved in the work, the designers can further optimize the final product. At present, the main development trends of hot runner molds at home and abroad can be summarized in the following aspects.

Miniaturization of components to realize the first mock examination with multiple cavities for small products and multi gate filling for large products. By reducing the nozzle space, more cavities can be configured on the mold, improving product production and injection machine utilization. In the 1990s, the nozzle developed by Master Company could reach a minimum of 15.875mm; The multi gate nozzle developed by Husky Company has 4 gates per nozzle, and the gate distance can be as close as 9.067mm; The composite nozzle developed by Osco company has 12 gate probes per nozzle, which can be used for forming 48 cavity molds. MoldMaters developed a nozzle for small parts in 2001, which includes an integral heater, needle tip, and melt channel. The volume diameter is less than 9mm, and the gate distance is only 10mm. It can be used to shape products with a weight of 1-30g; The mini hot runner system developed by Xieli Hot Runner Company has a gate distance of up to 8.00mm, especially suitable for smaller electronic products.

Currently, users demand shorter and shorter mold design and manufacturing cycles. Standardizing hot runner components not only helps to reduce design duplication and mold cost, but also facilitates the replacement and maintenance of vulnerable components. According to reports, Polyshot has developed a fast heat exchange runner mold system, especially suitable for small injection machines with an injection pressure of 70kN. The nozzles, valve stems, and splitter plates of companies such as Husky, Presto, and Moldmasters are all standard models for quick replacement and delivery of molds. Molds can be delivered in just 4 weeks abroad, and hot runner molds can be delivered as quickly as 2 weeks when produced in China.

The overall reliability of the hot runner mold design has been improved. At present, major mold companies at home and abroad attach great importance to the design of hot runner plate and the research and development of pressure distribution, temperature distribution, sealing and other issues of the connecting part of the hot nozzle. The development and utilization of laminated hot runner injection molds is also a hot topic. Stacked molds can effectively increase the number of cavities, while the requirement for injection machine clamping force only needs to be increased by 10% to 15%. Stacked hot runner molds have been used for industrialization in some developed countries abroad. Stacked hot runner molds have been widely used in the injection molding industry in China, such as disposable tableware, bottle caps, bottle cap anti-theft buckles, and handles. For example, the domestic Xieli Hot Runner Company has accumulated rich experience in the design, production, and use of stacked hot runners.

The purpose of improving the material of hot runner components is to improve the wear resistance of nozzles and hot runners, and to be used for the formation of sensitive materials. If ductile alloy materials such as molybdenum and titanium are used to manufacture nozzles, it has become possible to use metal powder injection molding and sintering to produce hot runner components.

Develop an accurate temperature control system. In hot runner mold molding, developing more precise temperature control devices to control the temperature of molten resin in the hot runner plate and gate is an effective measure to prevent resin overheating and degradation, as well as product performance degradation.

Use the hot runner for co injection. The effective combination design of branch pipes and thermal nozzle components can combine co injection molding with hot runner technology to form composite plastic products with 3, 5, or even more layers. For example, Kortec has developed a melt conveying system and co injection nozzle; Incoe's multi outlet, multi cavity co injection branch production line can be used for multi material and multi component co injection.