Advantages of a hot runner system:1. Shorten the processing cycle and improve efficiency;

2. Replacing the cold runner, thereby avoiding the production of raw material (nozzle material) and eliminating the need for further crushing;

3. Improve the appearance of the gate;

4. Reduce product stress and reduce product deformation;

5. Using valve gate for step-by-step injection molding, processing and manufacturing parts series with different specifications and sizes;

6. Improve more processing control to make precise adjustments to the injection molding process.

More advantages of a hot runner system:

More advantages of a hot runner system:1. Precise control of melt plastic temperature to eliminate material degradation;

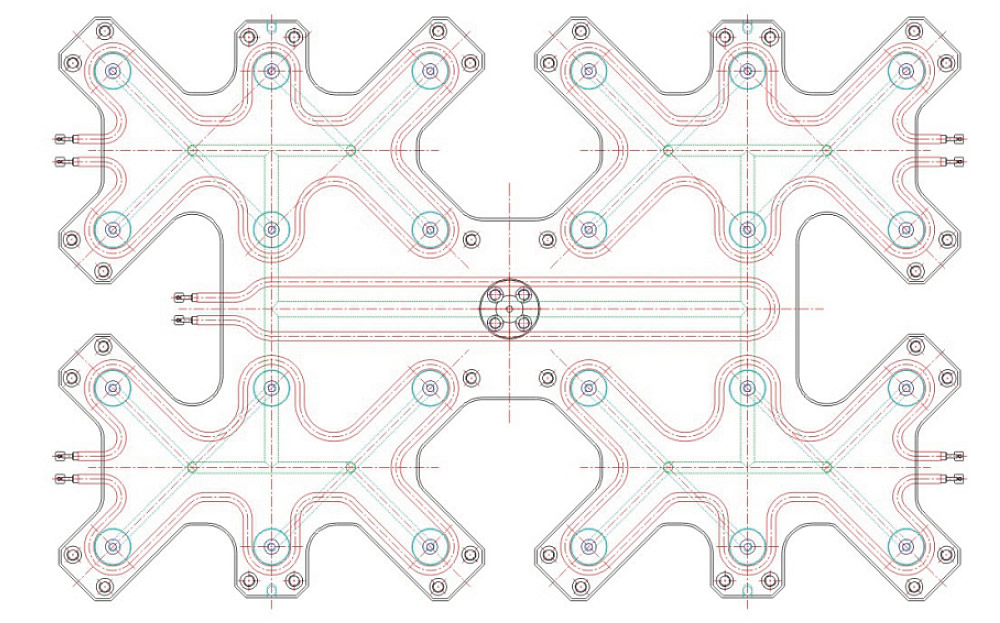

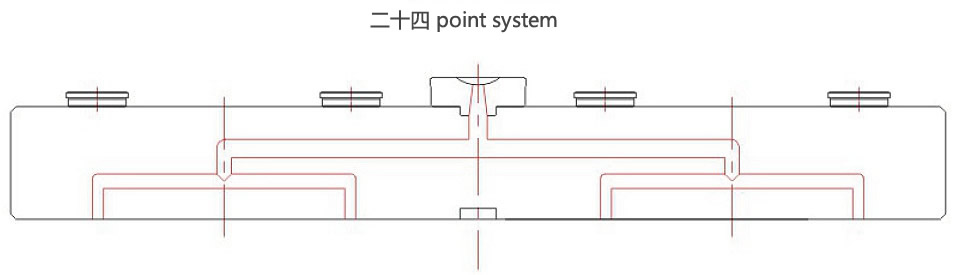

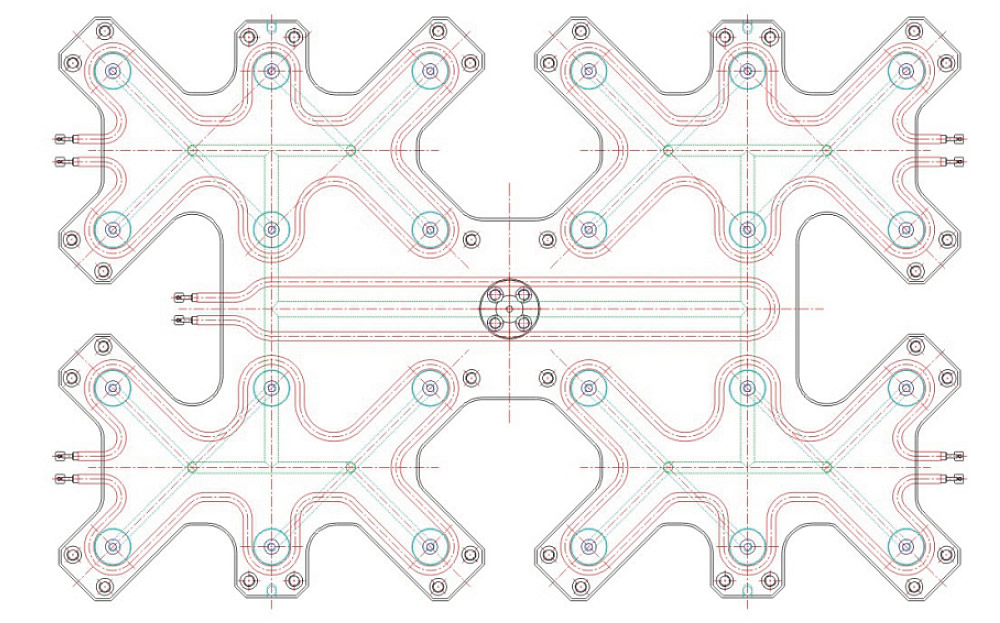

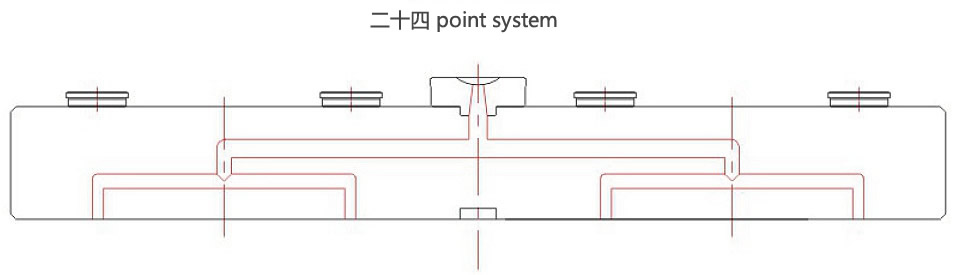

2. Balanced flow channel design, evenly filling the part cavity;

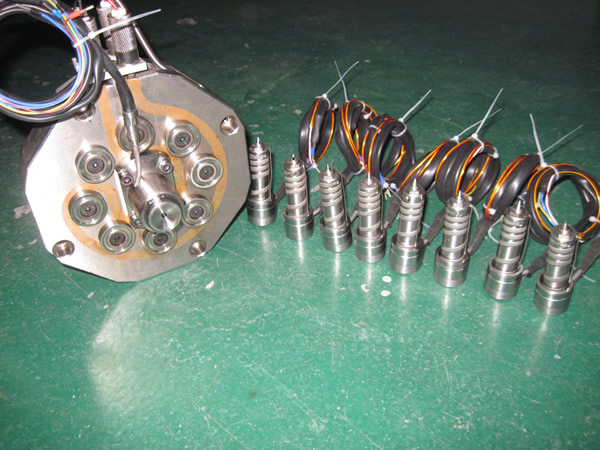

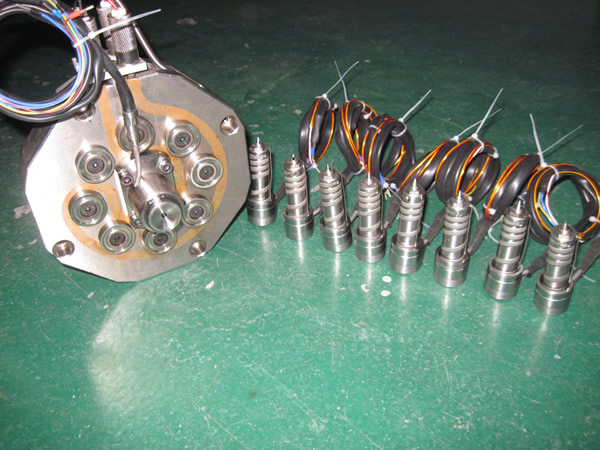

3. The appropriate size of the hot nozzle ensures smooth flow of the melt and sufficient filling of the mold cavity;

4. Correct gate structure and size, ensuring full filling of the mold cavity, and timely closure of needle valve gates to reduce casting and shorten

Injection molding cycle;

5. The flow channel has no intersecting areas, ensuring fast color change and preventing material degradation;

6. Minimize pressure loss;

7. Reasonable pressure holding time.