What are the classifications of hot runners?

Publisher: Administrator Date:2023-04-25

The hot runner system is divided into adiabatic hot runner and micro semi hot runner systems. The design of adiabatic flow channels is complex, but the effect is good and the maintenance cost is very low. The structure of micro semi hot runner is simplified, stable and easy to use, with low failure rate. Due to its simple structure, maintenance costs are low, providing greater assurance for production stability.

Hot runner classification: open type (for micro semi hot runners), needle valve type (for adiabatic runners).

The open structure is simple and suitable for micro semi hot flow channels, but not suitable for adiabatic flow channels. The adiabatic flow channels have high limitations on materials and directly come into contact with the product surface, which is prone to wire drawing and leakage, resulting in poor surface quality; The micro semi hot runner does not come into contact with the product but comes into contact with the micro runner, so an open hot nozzle can be used, which is widely used in high-precision molds abroad.

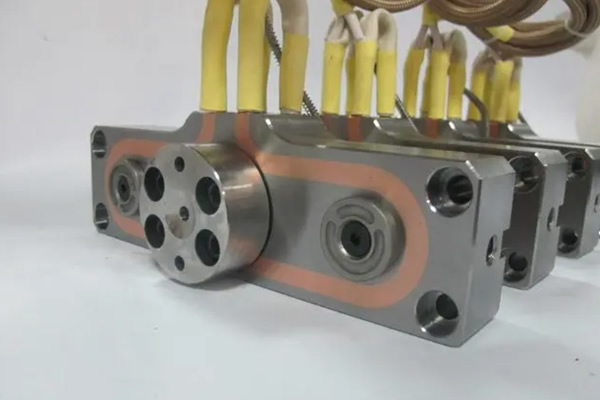

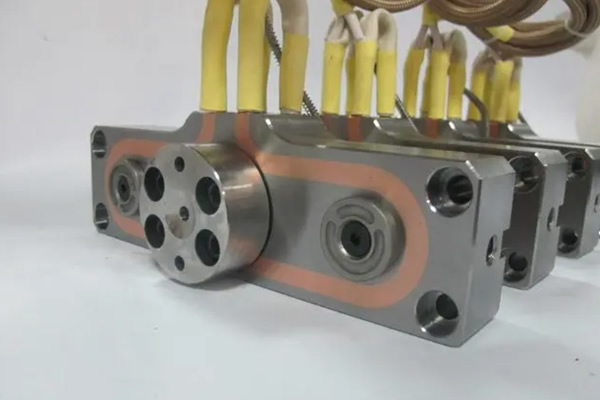

The needle valve type hot runner saves materials, and the surface of the plastic parts is beautiful, while the internal quality is tight and the strength is high.

Needle valve hot runner Needle valve hot runner (based on injection principle): cylinder type and spring type. The cylinder based controller and timing controller control the closure of the needle valve pushed by the cylinder, which has a complex structure but simple design.